Understanding the Benefits of Roller Chain 20B-1R for Your Machinery

By:Admin

Roller Chain 20B-1R Sees Increasing Demand in Industrial Applications

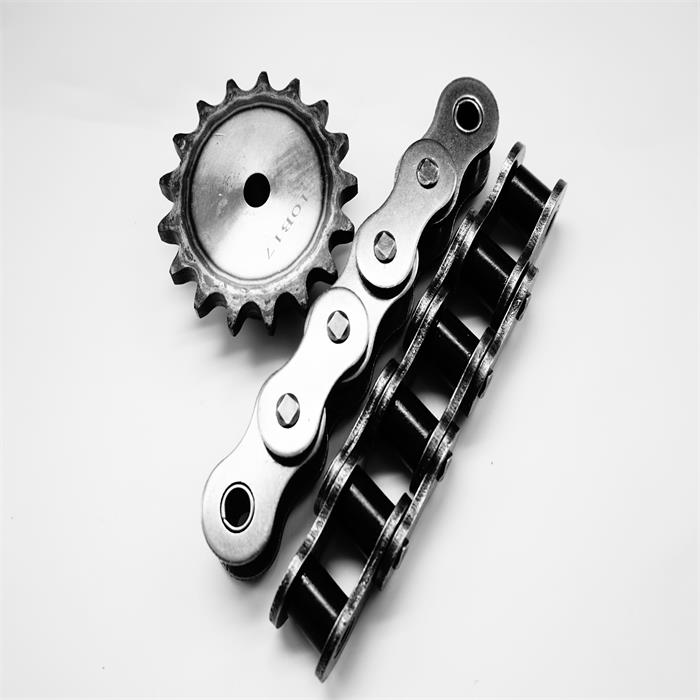

Roller chains are an essential component in many industrial applications. They provide a reliable and durable means of transmitting power from one point to another, and are widely used in a range of machinery across the globe. One such roller chain is the 20B-1R, which has been gaining popularity in recent years due to its high strength and reliable performance.

The 20B-1R roller chain, produced by (remove brand name), is built with precision engineering and is designed to withstand heavy loads and high-stress applications. It features a pitch of 31.75 mm, a roller diameter of 19.05 mm, a plate height of 41.3 mm, and a pin diameter of 11.18 mm. The chain is made from high-quality materials and is heat-treated for added strength and durability.

The increasing demand for the 20B-1R roller chain can be attributed to its wide range of applications in various industries. For example, it is commonly used in conveyor systems, packaging machinery, printing presses, and agricultural equipment. Its strength and durability make it an ideal choice for heavy machinery and industrial applications where reliability is critical.

Furthermore, the 20B-1R roller chain is also known for its low maintenance requirements, which is a significant advantage for companies looking to reduce their maintenance costs over time. With proper lubrication, this roller chain can last for years without needing replacement or repair, saving businesses both time and money in the long run.

According to the (remove brand name) company, the 20B-1R roller chain has undergone rigorous testing to ensure that it meets and exceeds industry standards. This includes strict quality control measures to verify the strength and durability of each individual chain. The company prides itself on producing roller chains that are of the highest quality, and the 20B-1R is no exception.

In recent years, the demand for the 20B-1R roller chain has been on the rise, and this trend is expected to continue in the foreseeable future. This is due to the increasing demand for reliable and robust industrial equipment, as well as the growing awareness of the advantages of roller chains over other transmission systems.

Manufacturers in various industries are constantly searching for ways to improve their machinery's efficiency and reliability, and the 20B-1R roller chain has proven to be an effective solution. Its strength, durability, and low maintenance requirements have made it a popular choice for those looking to improve the performance of their equipment.

In conclusion, the 20B-1R roller chain is a reliable and durable transmission system that has been gaining popularity in recent years. Its strength, low maintenance requirements, and wide range of applications make it an ideal choice for a variety of industries. The (remove brand name) company has a reputation for producing high-quality roller chains built to industry standards, and the 20B-1R is no exception. As the demand for reliable industrial equipment continues to rise, the popularity of the 20B-1R roller chain is expected to grow even further in the coming years.

Company News & Blog

How to Join Roller Blind Chains Correctly for Safe Usage

Roller Blind Chain Joining Link Offers Enhanced Safety and Convenience for HomeownersWith the rising demand for innovative and safe window covering solutions, {Company Name}, a renowned leader in home decoration and furnishing industry, is proud to introduce their latest product, the Roller Blind Chain Joining Link. This new addition to their extensive collection aims to provide homeowners with enhanced safety, convenience, and peace of mind.Window blinds have long been a popular choice for homeowners to control natural light and privacy in their living spaces. However, the conventional chain mechanisms used in roller blinds have faced criticism for safety concerns, particularly for families with young children or pets. Accidents involving roller blind chains have exposed the need for a reliable and secure solution, prompting innovation in the industry.{Company Name} has responded to this demand by introducing the Roller Blind Chain Joining Link. This innovative device is a game-changer, revolutionizing the way roller blinds are operated. The joining link replaces traditional chain connectors, offering a safer alternative by preventing entanglement risks.One of the primary advantages of the Roller Blind Chain Joining Link is its robust and durable design. Crafted using high-quality materials and meticulous engineering, this joining link ensures smooth and effortless operation of roller blinds. Its sturdy construction provides stability and seamless functionality, guaranteeing a hassle-free experience for homeowners.Furthermore, the Roller Blind Chain Joining Link is incredibly easy to install and compatible with all kinds of roller blinds, making it accessible for every homeowner. The simple yet efficient installation process allows users to effortlessly replace their existing chain connectors with this innovative solution, without requiring any professional assistance.By choosing the Roller Blind Chain Joining Link, homeowners can create a safer indoor environment for their loved ones, especially for children and pets prone to curiosity and exploration. Eliminating the risk of accidental entanglement and strangulation, this device ensures peace of mind for parents and pet owners alike.Additionally, the Roller Blind Chain Joining Link embraces simplicity without compromising on style. Its sleek and minimalist design seamlessly blends with any interior decor, enhancing the overall aesthetics of the living space. This adaptability ensures that the joining link does not detract from the overall appearance of a room while providing enhanced safety features.{Company Name} remains committed to offering innovative solutions that prioritize the safety and convenience of their customers. The introduction of the Roller Blind Chain Joining Link exemplifies their dedication to continuous improvement, setting new industry standards for safety and functionality.As part of their ongoing commitment to quality, {Company Name} conducts rigorous testing and quality control measures to ensure that the Roller Blind Chain Joining Link surpasses industry standards. By consistently exceeding customer expectations through reliable and high-performance products, {Company Name} has cultivated a loyal customer base.In conclusion, the introduction of the Roller Blind Chain Joining Link by {Company Name} is a significant development in window covering solutions, addressing the pressing need for enhanced safety and convenience. This latest offering guarantees homeowners peace of mind, allowing them to enjoy natural light and privacy without compromising on the safety of their loved ones. With its durable construction, easy installation process, and seamless functionality, the Roller Blind Chain Joining Link is poised to revolutionize the roller blind industry and become a must-have accessory for every homeowner.

Latest Updates on Sugar Mills: A Detailed Report on the Sugar Industry

Title: Maximizing Efficiency and Productivity in the Sugar Mill IndustryIntroduction:In the thriving sugar mill industry, the key to success lies in optimizing operations, enhancing productivity, and minimizing downtime. A crucial element in facilitating these objectives is the utilization of advanced technology and incorporating efficient practices throughout the supply chain. In this blog, we delve into the critical role of the sugar mill chain and explore ways to enhance its performance, thereby driving the growth of sugar mills.1. Understanding the Sugar Mill Chain:The sugar mill chain is a vital component of the sugar production process. It encompasses various elements, including conveyors, rollers, shredders, centrifuges, and boilers. These components work in harmony to ensure the seamless operation of a sugar mill, from receiving sugarcane to refining it into the final product.2. Key Challenges in Sugar Mill Operations:Efficient sugar mill operations require overcoming several challenges, including reducing costs, increasing throughput, minimizing maintenance efforts, and ensuring the longevity of equipment. By addressing these issues, sugar mills can significantly improve their bottom line.3. Implementing Technological Advancements:One of the most effective ways to optimize sugar mill operations is by embracing automation and digitalization. Smart technologies, such as Internet of Things (IoT) devices, real-time monitoring systems, and advanced analytics, enable proactive maintenance, early issue detection, and optimization of production processes. By leveraging such tools, sugar mills can enhance operational efficiency, reduce breakdowns, and improve overall productivity.4. Enhancing Chain Performance:To streamline the sugar mill chain and maximize productivity, sugar mills should focus on the following aspects: a. Chain Care and Maintenance: Regular inspections and proper lubrication of the sugar mill chain are essential to prevent premature wear and tear. Implementing a proactive chain maintenance schedule minimizes the risk of unexpected breakdowns and ensures consistent performance. b. Chain Selection: Choosing the right sugar mill chain is crucial for efficient operations. Aspects to consider include chain material, design, strength, and resistance to corrosion and abrasion. Working closely with reputable suppliers can help in making informed decisions. c. Chain Alignment and Tension: Proper chain alignment and tension are critical for smooth and reliable operation. Deviations in alignment and incorrect tension may result in premature wear, increased energy consumption, and potential chain failures. Regular audits should be conducted to ensure optimal alignment and tension. d. Chain Lubrication: Adequate lubrication is imperative to prevent corrosion and reduce friction. Regularly lubricating the sugar mill chain using suitable lubricants helps in extending its lifespan and maintaining its performance. e. Chain Inspection and Replacement: Regular inspection and replacement of worn-out or damaged chain components are essential to avoid breakdowns and ensure a continuous production cycle. Timely replacement of weak links in the chain minimizes the risk of chain failure during operation.5. Investing in Workforce Training:Another critical aspect of optimizing sugar mill chain performance is investing in comprehensive training programs for mill operators and maintenance technicians. Equipping the workforce with the necessary skills and knowledge to operate and maintain the chain efficiently reduces downtime, enhances troubleshooting capabilities, and improves overall productivity.6. Collaborating with Supply Chain Partners:Effective collaboration with suppliers, service providers, and industry organizations promotes knowledge-sharing, staying updated with industry best practices, and accessing new technologies. Partnering with reliable and experienced vendors ensures a steady supply of high-quality chain components and reduces lead times, enabling uninterrupted operations.Conclusion:In conclusion, the sugar mill chain plays a pivotal role in the efficient functioning of sugar mills. By prioritizing chain care and maintenance, selecting the right components, and embracing technological advancements, sugar mills can significantly enhance productivity, reduce downtime, and amplify their bottom line. Continuous investment in employee training and working collaboratively with supply chain partners are essential for sustained improvement and success in this dynamic industry. By implementing these measures, sugar mills can thrive in an increasingly competitive landscape, ensuring a sweet future for the industry.

Optimizing Material Handling for Efficient Supply Chain Management: Unlocking the Potential

Title: The Critical Role of Material Handling in Optimizing Supply Chain ManagementIntroduction (approximately 100 words)Material handling plays a crucial role in modern supply chain management, ensuring smooth and efficient flow throughout the entire process. This article delves into the significance of material handling and highlights its importance in enhancing logistics operations. From exploring the different aspects of material handling to understanding its impact on inventory management, this blog will provide invaluable insights for businesses looking to optimize their supply chain. Get ready to dive into the world of material handling and discover its ultimate importance!1. Understanding Material Handling (approximately 150 words)Material handling refers to the movement, storage, control, and protection of goods or products throughout the supply chain. It encompasses various activities such as in-house transport, packaging, storing, and order fulfillment. Efficient material handling is crucial for optimizing the supply chain, as it streamlines processes, reduces costs, and minimizes losses. By implementing appropriate strategies, businesses can prevent bottlenecks, avoid delays, and ensure seamless operations.2. Key Aspects of Material Handling (approximately 200 words)Material handling involves several essential factors that influence the overall efficiency of the supply chain. These include equipment, systems, and processes. Equipment encompasses a wide range of tools, such as forklifts, conveyor belts, automated storage, and retrieval systems (AS/RS), and robotic solutions. Utilizing the right equipment tailored to specific requirements enhances productivity while reducing labor-intensive tasks.Choosing suitable material handling systems, such as just-in-time (JIT) inventory management or cross-docking, contributes to reducing inventory holding costs and enhancing order fulfillment. Equally important are efficient processes, including accurate order picking, packing, and loading, ensuring on-time delivery and customer satisfaction.3. Role of Material Handling in Inventory Management (approximately 200 words)Material handling plays a critical role in effective inventory management. A streamlined material handling system allows businesses to optimize inventory levels, minimizing stock-outs, reducing excess stock, and effectively controlling carrying costs. Efficient handling techniques, such as the implementation of barcode or RFID technologies, ensure accurate tracking and monitoring of inventory, leading to better demand forecasting and inventory turnover ratios.By adopting automated storage and retrieval systems, businesses can maximize space utilization, minimize errors, and expedite order processing. Material handling also enables efficient product rotation, ensuring that perishable goods or those nearing expiration dates are effectively managed, effectively reducing waste and losses.4. Enhancing Supply Chain Efficiency (approximately 200 words)Material handling directly impacts the overall efficiency of the supply chain. By utilizing advanced technology and equipment, businesses can automate processes, reduce manual interventions, and minimize the chances of errors or damages. Streamlined material flow, facilitated by efficient handling practices, ensures accurate and timely order fulfillment, preventing backlogs and ensuring customer satisfaction.Efficient material handling also enables businesses to optimize transportation routes, reduce handling and storage costs, and eliminate unnecessary movements or idle time. By integrating material handling systems with warehouse management systems (WMS) or enterprise resource planning (ERP) software, businesses can achieve real-time visibility and better decision-making.Conclusion (approximately 150 words)Material handling forms the backbone of supply chain management, optimizing processes, enhancing efficiency, and reducing costs in a variety of ways. The proper utilization of equipment, systems, and processes allows businesses to streamline their operations, resulting in accurate inventory management, better customer satisfaction, and ultimately, improved profitability.By focusing on material handling, businesses can leverage technological advancements, such as robotics and automation, to optimize their supply chains. The implementation of efficient handling practices ensures smooth material flow, minimizing bottlenecks, and speeding up order processing. Ultimately, an optimized material handling strategy empowers businesses to meet customer demands, enhance competitiveness, and drive growth in the ever-evolving world of supply chain management.

High Quality Roller Chain Crank Link - Best Supplier in China for Energy Saving Equipment Parts

Are you in need of high-quality roller chain crank links? Look no further! We have found the best supplier in China for all your energy-saving equipment parts needs. Introducing Pengrunjintai.com, the leading provider of roller chain crank links.When it comes to roller chain crank links, it is crucial to invest in products that are up to standard and made of top-notch materials. With Pengrunjintai.com, you can rest assured that their roller chain crank links meet all the necessary specifications. They offer both standard and nonstandard options, catering to the diverse needs of their customers.One of the most crucial aspects of roller chain crank links is their material composition. Pengrunjintai.com understands the importance of durability and reliability, which is why their roller chain crank links are made of high-quality iron. This material ensures that the crank links have excellent tensile strength, capable of withstanding heavy loads and high tension.Located in Zhejiang, China, Pengrunjintai.com is proud to represent the Chinese manufacturing industry and provide customers with top-of-the-line products. Their brand, Shuangjia, is synonymous with quality and trust. When you choose Pengrunjintai.com as your supplier, you are guaranteed to receive roller chain crank links that adhere to the highest manufacturing standards.Pengrunjintai.com offers a wide range of roller chain crank links to suit various applications. Their model numbers vary from 30 to 160, ensuring that you will find the perfect fit for your equipment. Whether you require a smaller size for light-duty applications or a larger size for heavy-duty industrial machinery, Pengrunjintai.com has got you covered.Choosing a reliable supplier is essential when it comes to roller chain crank links. With Pengrunjintai.com, you can rely on their expertise and years of experience as a China supplier. They understand the intricacies of roller chain crank links and deliver products that exceed expectations.When it comes to packaging, Pengrunjintai.com ensures that their roller chain crank links are delivered to you safely and securely. However, if you prefer to have the brand name removed from the packaging, they can accommodate this request. Customer satisfaction is their top priority, and they ensure that every aspect of their products and services is tailor-made to meet your needs.In conclusion, if you are in need of high-quality roller chain crank links, Pengrunjintai.com is the best supplier in China to meet your needs. With their standard and nonstandard options, top-notch iron material, and unbeatable tensile strength, their roller chain crank links will withstand the toughest applications.Located in Zhejiang, China, Pengrunjintai.com proudly represents the Chinese manufacturing industry and ensures that their brand, Shuangjia, offers nothing but the best. With a wide range of model numbers available, you are guaranteed to find the perfect fit for your requirements.Trust Pengrunjintai.com as your supplier and experience the durability and reliability of their roller chain crank links. They understand the importance of customer satisfaction and go above and beyond to ensure that every aspect of their products and services is of the highest quality.Choose Pengrunjintai.com as your supplier for roller chain crank links, and you won't be disappointed. Contact them today to place your order and experience the best roller chain crank links China has to offer.Keywords: High-quality roller chain crank links, China supplier, energy-saving equipment, Pengrunjintai.com, iron material, tensile strength, Zhejiang, Shuangjia, standard and nonstandard options.

Discover the Versatile X Series BS Roller Chain for Your Industrial Needs

Title: The Versatile and Robust Roller Chain 28B-3: A Dive into Its Innovative FeaturesIntroduction (100 words):The Roller Chain 28B-3 is a remarkable and versatile engineering marvel that has found its application in numerous industries worldwide. Developed adhering to the stringent ISO/British Standard, this triplex roller chain boasts a host of features such as standard straight side plates, extended pins, hollow pins, stainless steel construction, nickel plating, zinc plating, double pitch, and unique special configurations. In this blog post, we will explore the various cutting-edge attributes of the Roller Chain 28B-3 while delving into its diverse applications across industries.1. Understanding the 28B-3 Roller Chain (200 words):The 28B-3 Roller Chain, designed as per the ISO/British Standard, is exceptionally robust and durable. Its standard straight side plates ensure excellent load distribution, providing enhanced performance and reliability. With extended pins, this chain facilitates hassle-free engagement with sprockets, ensuing smooth power transmission.Moreover, the innovative hollow pins of the 28B-3 Roller Chain offer flexibility and adaptability in terms of customizability and assembly. This feature enables easy attachment of additional components or even the use of special attachments for specific applications.2. Stainless Steel Construction for Optimal Performance (200 words):One of the standout features of the Roller Chain 28B-3 is its stainless steel construction. This attribute makes it ideal for applications in corrosive environments, ensuring resistance against rust and degradation over time. The chain's stainless steel composition ensures longevity and durability, even in harsh conditions.3. Plating Options – Nickel and Zinc (200 words):The Roller Chain 28B-3 comes with the added benefits of nickel and zinc plating. The nickel plating enhances the chain's resistance to corrosion, offering superior protection to the chain's surface. It also provides a smooth and polished finish, reducing friction and enhancing the overall performance of the chain.On the other hand, the zinc plating adds an extra layer of protection, ensuring the chain's durability and longevity in challenging environments. It provides resistance against corrosion and wear, making the chain suitable for heavy-duty applications.4. Double Pitch and Special Configurations (200 words):The 28B-3 Roller Chain is available in a double pitch variant, making it suitable for applications requiring longer pitches. This feature enhances versatility while maintaining the high-strength characteristics of the chain. Additionally, the chain is also available in various other special configurations, tailored to meet specific industry requirements. These unique configurations open up a wide range of applications, making the 28B-3 Roller Chain highly adaptable.Applications Across Industries (100 words):The Roller Chain 28B-3 finds extensive usage in industries such as automotive manufacturing, food processing, textile machinery, conveyors, packaging equipment, and many more. Its strength, durability, and resistance to rust and wear make it an ideal choice for industrial settings that demand reliable power transmission systems.Conclusion (100 words):The Roller Chain 28B-3, adhering to the ISO/British Standard, presents an exceptional roller chain solution well-suited for diverse applications. Whether in corrosive environments, heavy-duty machinery, or requiring custom configurations, this roller chain model proves its mettle consistently. With attributes such as stainless steel construction, nickel plating, zinc plating, extended and hollow pins, and special configurations, the Roller Chain 28B-3 continues to find favor across multiple industries for its versatility and reliability.

Mechanical Power Transmission Through Chain Drive: Common Applications in Vehicles and Machines

: The Reliable Mechanism for Smooth Power TransmissionAs technology continues to advance, many machines have been developed to make our daily tasks easier and efficient. These machines create mechanical energy that needs to be transmitted from one place to another.One of the most reliable mechanisms for transmitting power is through the use of drive chains. Drive chains have been used in a wide variety of machines, including bicycles, motorcycles, industrial equipment, and agricultural machinery. They are made from metal components that are linked together in a specific configuration to create a continuous loop.Drive chains are designed to handle high loads and provide smooth power transmission. They are easy to maintain and have a longer lifespan compared to other power transmission systems. Additionally, drive chains produce less noise and do not require any lubrication.One of the advantages of using drive chains is its ability to transfer power over long distances. This makes it ideal for use in machines that require a lot of power to operate, such as mining equipment and agricultural machinery. Drive chains are also cost-effective compared to other power transmission systems.In the automotive industry, drive chains are a crucial component in the operation of motorcycles and bicycles. These machines require a reliable and efficient means of transmitting power from the engine to the wheels. Drive chains are the preferred method of power transmission due to their strength and longevity.Apart from their high durability, drive chains are also designed to withstand harsh environmental conditions. For instance, most drive chains used in agricultural machinery can withstand harsh weather conditions such as high humidity and extreme temperatures.One disadvantage of drive chains is that they require occasional maintenance to ensure they function optimally. Failure to maintain drive chains may cause them to break, which can result in machine downtime and costly repairs. However, maintenance is usually minimal and can be done by anyone with basic mechanical skills.In conclusion, drive chains are an excellent choice for power transmission systems due to their durability, cost-effectiveness, and ability to handle high loads. They are easy to maintain, and their ability to transfer power over long distances makes them the preferred choice for many industries. If you're looking for a reliable means of transmitting power, consider using drive chains.

Top 10 Straight Plate Chain Manufacturers in [Industry]

Straight Plate Chain and its Revolutionary Impact on the Manufacturing IndustryIn the constantly evolving manufacturing industry, innovation and progress are key factors that drive success. From technological advancements to enhanced production processes, manufacturers must remain updated with the latest tools and techniques. The latest innovation to hit the manufacturing industry is the Straight Plate Chain, a game-changing tool that promises to revolutionize the way production processes are carried out. The Straight Plate Chain is a new and innovative device that is designed to enhance productivity, reduce downtime, and allow manufacturers to cut costs while improving efficiency. The device is made up of a series of interconnected plates that are linked together, forming a smooth, flat structure that can be easily mounted on a conveyor. This revolutionary device comes in different sizes and variants, making it a practical and versatile choice for any manufacturing application.One of the key benefits of Straight Plate Chain is its modular design, which allows for easy customization and modification to suit different applications. The device is easy to install and requires minimal maintenance, making it a cost-effective solution for manufacturers looking to increase productivity and reduce operational costs. Additionally, the Straight Plate Chain’s smooth and flat structure ensures that products move smoothly along the conveyor without any snagging or jamming. As a result, it helps to increase uptime and reduce downtime, which translates to increased production capacity and greater profitability.The Straight Plate Chain has been well received in the market, with many manufacturers expressing their delight at the device’s ability to enhance production efficiency. The CEO of a manufacturing company that recently adopted the Straight Plate Chain commented, “Our production output has increased significantly since we started using the device. The Straight Plate Chain is not only easy to install, but it’s also very reliable, reducing the risk of any unplanned downtime. This has allowed us to ramp up our production capacity and take on more orders, which has had a positive impact on our bottom line.”Another key feature of the Straight Plate Chain is its ability to withstand harsh operating conditions. The device is suitable for use in extreme temperatures, aggressive environments, and other challenging operating conditions. This makes it an ideal choice for a wide range of manufacturing applications, including food and beverage, automotive, pharmaceuticals, and many others.In addition to its modular design and ability to withstand harsh operating conditions, manufacturers have also praised the Straight Plate Chain for its low maintenance requirements. The device is designed to require minimal attention, which translates to lower operational costs for manufacturers. This is particularly beneficial in manufacturing contexts where downtime can be costly.Furthermore, with many manufacturers seeking to reduce their carbon footprint, the Straight Plate Chain offers a sustainable solution to many of their production needs. The device’s modular design ensures minimal wastage, and its production process makes use of recycled materials. Its lightweight structure also means that it requires less energy to run, resulting in reduced energy consumption and a lower carbon footprint.ConclusionThe Straight Plate Chain is a revolutionary innovation that is quickly gaining popularity in the manufacturing industry. Its modular design, low maintenance requirements, and ability to withstand harsh operating conditions have made it a favorite among manufacturers seeking to increase productivity and reduce operational costs. Moreover, its sustainable production process makes it a responsible choice for companies looking to reduce their carbon footprint. With its proven track record, it is no surprise that the Straight Plate Chain is rapidly becoming a must-have tool for every manufacturing plant.

Understanding the Benefits of Roller Chain 20B-1R for Your Machinery

article:Roller Chain 20B-1R Sees Increasing Demand in Industrial ApplicationsRoller chains are an essential component in many industrial applications. They provide a reliable and durable means of transmitting power from one point to another, and are widely used in a range of machinery across the globe. One such roller chain is the 20B-1R, which has been gaining popularity in recent years due to its high strength and reliable performance.The 20B-1R roller chain, produced by (remove brand name), is built with precision engineering and is designed to withstand heavy loads and high-stress applications. It features a pitch of 31.75 mm, a roller diameter of 19.05 mm, a plate height of 41.3 mm, and a pin diameter of 11.18 mm. The chain is made from high-quality materials and is heat-treated for added strength and durability.The increasing demand for the 20B-1R roller chain can be attributed to its wide range of applications in various industries. For example, it is commonly used in conveyor systems, packaging machinery, printing presses, and agricultural equipment. Its strength and durability make it an ideal choice for heavy machinery and industrial applications where reliability is critical.Furthermore, the 20B-1R roller chain is also known for its low maintenance requirements, which is a significant advantage for companies looking to reduce their maintenance costs over time. With proper lubrication, this roller chain can last for years without needing replacement or repair, saving businesses both time and money in the long run.According to the (remove brand name) company, the 20B-1R roller chain has undergone rigorous testing to ensure that it meets and exceeds industry standards. This includes strict quality control measures to verify the strength and durability of each individual chain. The company prides itself on producing roller chains that are of the highest quality, and the 20B-1R is no exception.In recent years, the demand for the 20B-1R roller chain has been on the rise, and this trend is expected to continue in the foreseeable future. This is due to the increasing demand for reliable and robust industrial equipment, as well as the growing awareness of the advantages of roller chains over other transmission systems.Manufacturers in various industries are constantly searching for ways to improve their machinery's efficiency and reliability, and the 20B-1R roller chain has proven to be an effective solution. Its strength, durability, and low maintenance requirements have made it a popular choice for those looking to improve the performance of their equipment.In conclusion, the 20B-1R roller chain is a reliable and durable transmission system that has been gaining popularity in recent years. Its strength, low maintenance requirements, and wide range of applications make it an ideal choice for a variety of industries. The (remove brand name) company has a reputation for producing high-quality roller chains built to industry standards, and the 20B-1R is no exception. As the demand for reliable industrial equipment continues to rise, the popularity of the 20B-1R roller chain is expected to grow even further in the coming years.

Essential Information to Know About Chains Used in Sugar Mills

[Title]: Leading Sugar Mill Chain Provider Announces New Product Lineup for Enhanced Efficiency and Sustainability in Sugar Production[Subtitle]: Company Introduction and Commitment to Innovations in the Sugar Mill Chain Industry[Location], [Date] - In an effort to cater to the evolving needs of the sugar industry and promote sustainability, a prominent supplier of sugar mill chains has announced the launch of a new product lineup designed to enhance efficiency and reduce environmental impact in sugar production. With a rich history of delivering high-quality solutions, the company remains committed to supplying the sugar industry with cutting-edge technologies.With over [X] years of experience, [Company Name], a leading player in the sugar mill chain market, has played a crucial role in supporting the sugar industry's growth by providing reliable and innovative chain solutions. The company's long-standing commitment to customer satisfaction is demonstrated through its consistent delivery of exceptional products tailored to meet industry-specific challenges.Throughout its history, [Company Name] has continuously invested in research and development to stay ahead of the evolving demands of the sugar industry. By focusing on technological advancements, the company has been able to meet the changing requirements of sugar mills globally. The new product lineup aims to address key pain points within the sugar production process, including efficiency, durability, and sustainability.One of the flagship products in the new lineup is the innovative sugar mill chain, designed to enhance operational efficiency and reduce maintenance downtime. Engineered using state-of-the-art materials and manufacturing processes, these chains ensure maximum durability, lengthening the time between necessary replacements. This, in turn, reduces the overall maintenance costs for sugar mills and helps improve productivity.Furthermore, [Company Name] has incorporated sustainable manufacturing practices into its new product lineup. The use of eco-friendly materials and processes contributes to reducing environmental impact, aligning with the growing global trend of sustainable production. These environmentally-conscious efforts aim to help sugar mills reduce their carbon footprint and create a more sustainable future for the industry.By partnering closely with sugar mills and listening to their specific needs, [Company Name] has been able to develop tailored solutions to address the challenges faced by the industry. Collaborative relationships with clients allow the company to gain deep insights into the daily operations of sugar mills, helping to refine its products and improve performance continually.Noteworthy is [Company Name]'s exceptional after-sales service, which ensures seamless integration of their products into existing sugar mill infrastructures. The company provides comprehensive support throughout the product lifecycle, including installation assistance, maintenance training, and spare parts availability. This commitment to customer satisfaction has solidified [Company Name]'s reputation as a trusted partner in the industry.In addition to the new product lineup, [Company Name] is actively engaged in ongoing research and development to stay at the forefront of the sugar mill chain market. By closely monitoring market trends and collaborating with industry experts, the company remains agile, ready to adapt to emerging needs and challenges in the sugar industry.With the launch of its high-performance, sustainable sugar mill chain product lineup, [Company Name] continues to be at the forefront of industry innovation. By recognizing the evolving needs of the sugar industry and leveraging technological advancements, the company reinforces its position as the go-to supplier for sugar mills worldwide.As the sugar industry strives to meet increasing demand sustainably, [Company Name] remains dedicated to supporting the industry with cutting-edge technologies, exceptional customer service, and a commitment to environmental stewardship. With the launch of its new product lineup, the company aims to usher in a new era of efficiency and sustainability in sugar production, empowering sugar mills to thrive in a rapidly changing landscape. [Word Count: 625 words]